FUTURO sheds

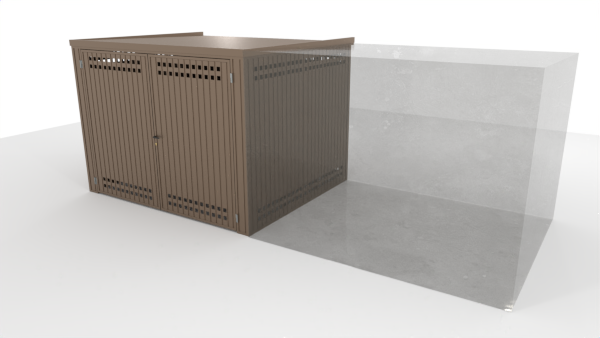

FUTURO sheds are modern and comprehensive solutions with a wide range of applications. They are made in an automated technological process using welding robots that guarantee full repeatability.

All technological holes are cut with a laser, and the connections are inverter welded without the use of rivets. After making holes, connections and galvanizing, all elements, including the handle and hinges, are powder coated in RAL 8028 or RAL 7024 as standard. The assembly of the shed is non-invasive, which means there is no need to drill additional holes in its elements.

For greater safety, FUTURO sheds have a doubled distribution of vertical and lateral loads. Ventilation is provided by the upper and lower horizontal system used as standard on all four walls. The shed is closed, depending on the model, with single-leaf, swing or sliding doors equipped with a lock or padlock handle.

Colours and designs

|

|

|

The colors presented on the LEGBUD GARGULA website should be treated as indicative only.

Dimensions

| width x height x length mm |

| 2950 x 2180 x 3020 |

| 2970 x 2180 x 2520 |

| 2970 x 2180 x 4980 |

Features

Powder coating - colour from the RAL palette

Powder coating in a non-standard RAL colour according to individual arrangements.

Installation on screw foundations

Mounting to the ground using screw foundations (KRINNER screws).

Canopy

Additional roof on selected side – front, back, left side, right side.

Added shed

Construction of a shed combined with another LEGBUD GARGULA product (garden room, garage, carport).

Online catalogues

Download and view LEGBUD GARGULA product catalogues.

Download

See technical data sheets and assembly instructions for our products.

Distribution

Check where you can purchase LEGBUD GARGULA products in your area.

Contact

Our consultants will be happy to answer your questions. Contact us by phone, email or contact form.

English

English  Polski

Polski  Deutsch

Deutsch  Français

Français  Italiano

Italiano  Čeština

Čeština  Slovenčina

Slovenčina  Magyar

Magyar  Русский

Русский